In the ever-evolving landscape of digital technology, outdoor LCD displays have emerged as a game-changer in the world of advertising and public information dissemination.

View More

In the LED manufacturing industry, the choice between HOB (High Optical Brightness) and GOB (General Optical Brightness) technologies can significantly impact the quality and performance of the final product. This article will explore the advantages of HOB technology over GOB, based on a comparative analysis of their processes and outcomes.

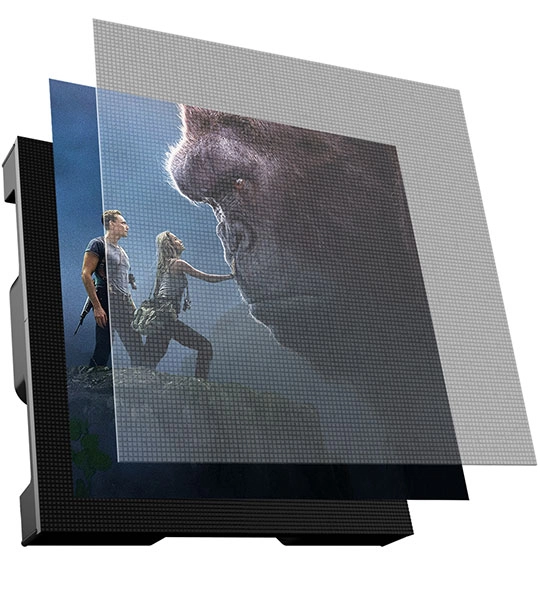

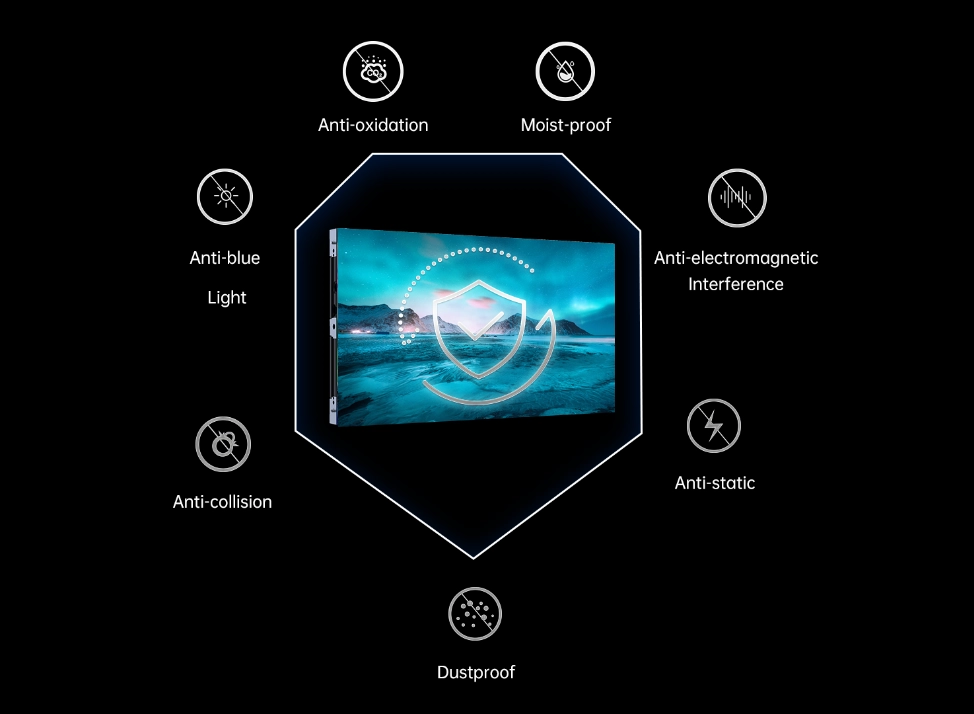

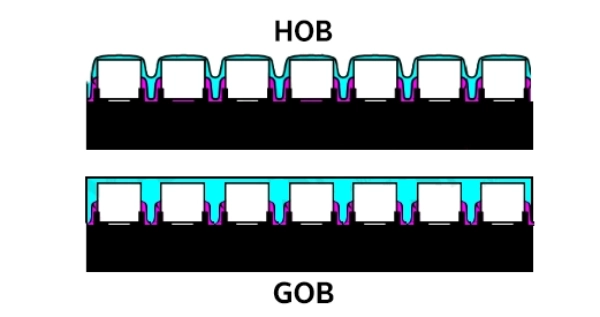

GOB stands for Glue On Board, an advanced packaging technology used for LED display screens. This technology involves injecting a special optical thermal conductive nanometer-grade potting material between the LED lamps and the PCB (Printed Circuit Board) to enhance the stability of the connections between the lamps and provide various protective functions such as waterproofing, moisture-proofing, dust-proofing, anti-shock, anti-static, and more.

A GOB LED module is an LED display made using GOB technology, featuring high protectiveness and the ability to work in a variety of harsh environments, such as outdoors or indoors. This comprehensive protective function is particularly suitable for indoor small-pitch LED displays, ensuring their stability and durability in complex environments. Moreover, GOB technology integrates the midstream packaging and downstream display technology of the LED industry, saving costs in the manufacturing process and increasing production efficiency. Additionally, the cost of GOB LED modules is relatively low, which can reduce the overall cost when manufacturing indoor small-pitch LED displays.

HOB stands for High Optical Brightness, which refers to a state-of-the-art LED packaging technology. This technique involves injecting a special optical thermal conductive nanometer-grade potting material between the LED lamps and the PCB (Printed Circuit Board) to enhance the stability of the connections between the lamps and to provide various protective functions such as waterproofing, moisture-proofing, dust-proofing, anti-shock, and anti-static properties. The features of HOB technology include superior stability, comprehensive protection, excellent optical performance, and efficient heat dissipation.

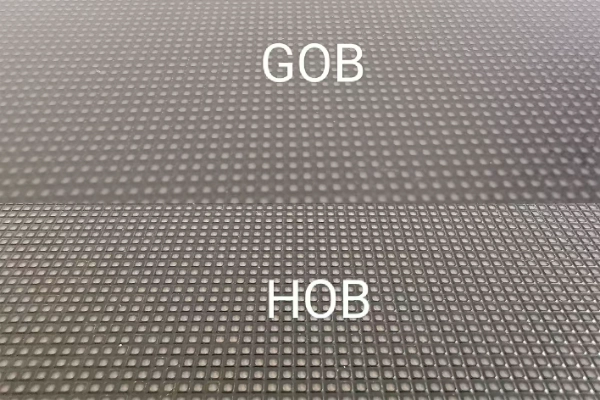

HOB uses a high-temperature molding process, while GOB uses a normal-temperature dispensing process. HOB has better thermal stability, accuracy, flatness, and thickness control than GOB. Moreover, high-temperature molding can prevent the glue from cracking due to heat generation during LED operation causes the undesirable phenomenon of dead lights.

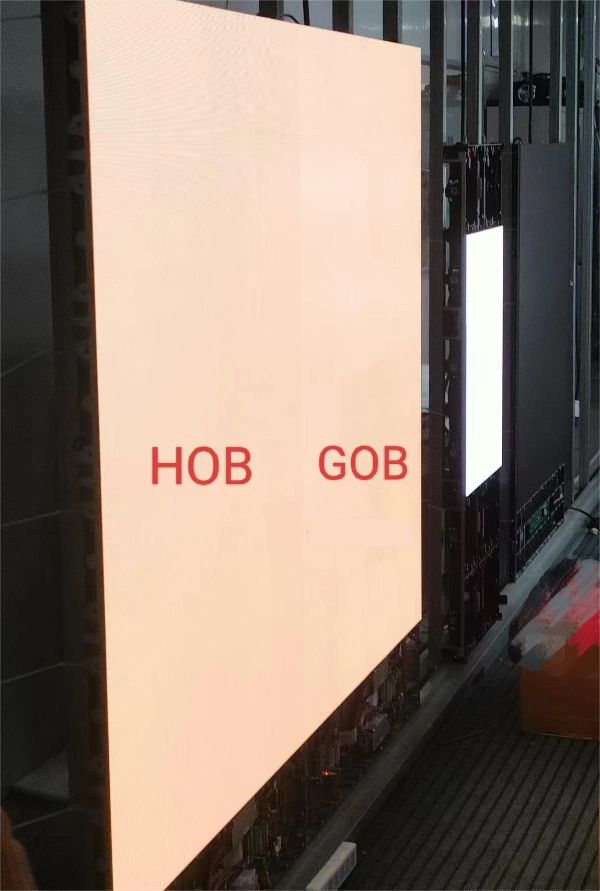

HOB technology excels in providing a natural and smooth granular texture to the LED surface, which is a result of its one-time curing process. This addresses the issues of flat mirror-like reflections and uneven micro-granularity often seen in GOB technology. Furthermore, HOB's tunnel furnace curing process ensures consistent ink color, unlike GOB, which can suffer from color variations due to its longer curing cycle that involves surface drying for 2-3 days and deep curing over 3-6 months.

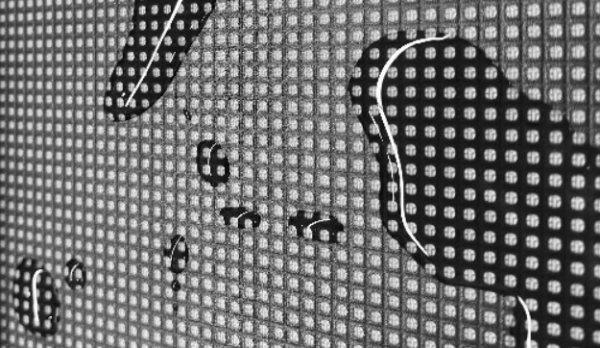

GOB and HOB ink color consistency contrast

The flatness of HOB is superior, as it utilizes fully automated equipment with specialized jigs for vacuum glue filling and tunnel furnace curing, which solves the issue of poor flatness associated with GOB's room temperature curing. Additionally, HOB's uniform colloid thickness contributes to better light damage and heat dissipation compared to GOB, reducing potential issues with the lifespan of the LEDs.

GOB LED Display poor flatness |

GOB LED Display defect reflect light |

The surface of the final product of the ordinary GOB process is a mirror surface, which cannot achieve a frosted or matte surface.

HOB uses mold design and pressure molding to create a frosted surface, which is similar to matte black light. This increases the contrast of the entire screen by 40%.

In terms of display effects, HOB technology ensures that there is no light leakage between seams, a common issue with GOB's mirror-like light sources that can lead to light leakage and easier modularization. HOB also improves the appearance of ink color and eliminates the yin and yang face effect, allowing customers to avoid the need to manually select and color-match boards as is often required with GOB technology.

HOB technology demonstrates superior performance in terms of temperature resistance, withstanding a range of -20℃ to +80℃, compared to GOB, which can lead to module deformation at around -5℃. This makes HOB more reliable in extreme temperature conditions. Moreover , HOB's high-temperature curing process ensures that the glue retracts around the LEDs, providing long-term protection against pulling and potential cold welding of the LEDs, a problem that can arise with GOB due to its longer curing times.

HOB adopts the COB process of high-temperature molding with a polymer synthetic colloid, which contains various additives, coagulants, and anti-UV agents. This can prevent the yellowing problem of ordinary epoxy, and also adjust the black pigment and design the mold frosted surface.

Anti-Scratch and Water-Proofing, Moisture-Proofing, Dust-Proofing, Anti-shock, and Anti-Static properties.

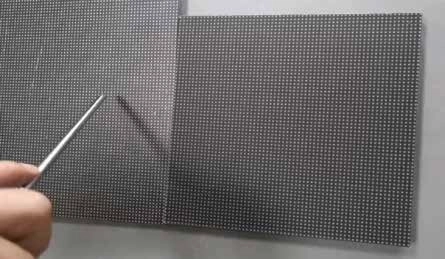

When you place a conventional GOB product and a HOB product side by side, and scratch the surface with a screwdriver, you will see a clear difference. The GOB product is not scratch-resistant and will show scratches and cracks immediately, while the HOB product will remain intact. This is because the HOB product uses the COB process of high-temperature molding with a polymer synthetic colloid, which has various additives, coagulants, and anti-UV agents. This can avoid the yellowing problem of common epoxy, and also modify the black pigment and create the mold frosted surface.

|  |

GOB process has a variable thickness of the final product, and a difference in the flatness of the self-leveling colloid, which results in a thicker GOB product. This causes a more noticeable edge refraction problem when splicing on a large scale, which is commonly known as the bright line problem of the writing angle.

HCOB uses precision molding tools, which ensure that its thickness is only up to 0.2mm higher than the LED height, and the light hardly undergoes secondary refraction at the edge of the colloid.

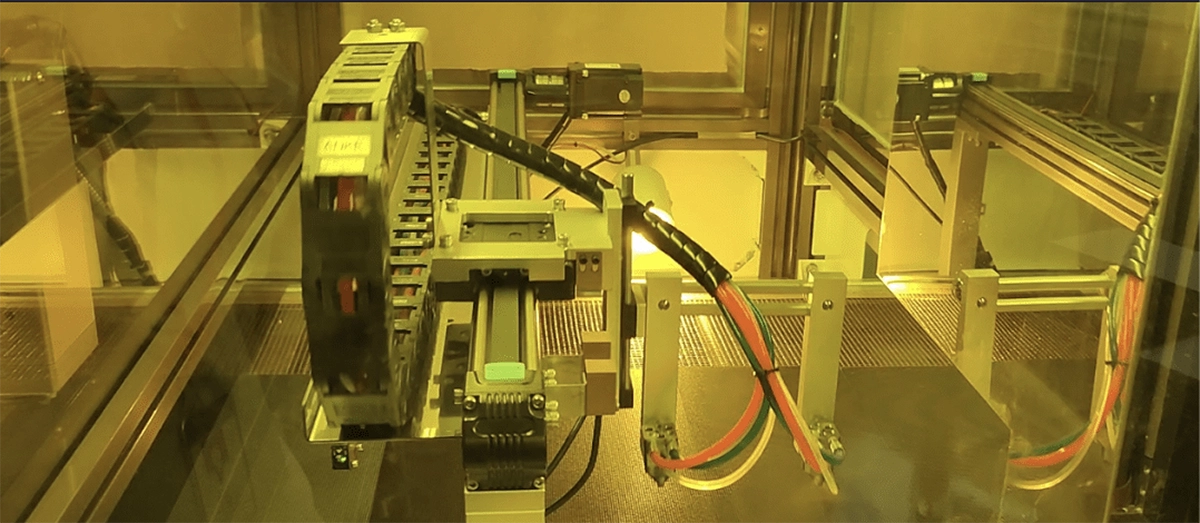

The production process of HOB is more advanced, utilizing fully automated equipment. This includes integrated mold formation, automatic imaging inspection, and a 40-meter long high-temperature automatic line that can complete the process in just 1.5 hours. This not only ensures consistent quality but also significantly reduces production time and enhances delivery efficiency. In contrast, GOB relies on manual or semi-automatic equipment, which can lead to inconsistencies and longer production times.

HCOB uses high-precision mold technology, which allows the overall molding accuracy to be controlled within 0.2mm, according to conventional mold precision. GOB uses room temperature molding, which depends on the molecular internal coagulation curing, and has a shrinkage problem. The best progress of GOB so far is 0.5mm, and some products need secondary processing. HCOB technology has been applied in batches on the mainstream pitches of 1.2, 1.5, and 1.8.

Platform information submission - privacy agreement

● Privacy Policy

We are committed to protecting the privacy, personal data and personal data (collectively referred to as "personal data") provided by you when using this website. Make us comply with the highest standards in terms of collection, use, storage and transmission of personal data (laws and regulations related to privacy of personal data) and consumer protection. To ensure that you have full confidence in the handling of personal data on this website, you must carefully read and understand the provisions of the privacy policy. This website (hereinafter referred to as "us") respects and protects the privacy of users. In particular, once you use this website, you will be deemed to accept, agree, promise and confirm this privacy agreement; You disclose your personal data to us voluntarily with the required consent; You will abide by any modification of this privacy policy; You agree that our relevant business personnel will contact you regarding the products and services you may be interested in (unless you have indicated that you do not want to receive such messages). With your consent, we will collect, manage and monitor the types of personal data collected

1. Scope of application

It is our unremitting pursuit to provide users with better, better and more personalized services. We also hope that the services we provide will be more convenient for your needs. This privacy policy applies to all information collection services provided by this website. You can visit this website and use the services provided by this website using this privacy policy

2. What information do we collect

In order to provide you with our various services, you need to provide personal data information, including personal data and anonymous data, including but not limited to: personal data (your name, gender, age, date of birth, telephone number, fax number, address or mailing address, e-mail address, etc.)

3. How to use the collected information

The purposes and purposes of collecting personal data and anonymous data are as follows: to provide you with our services through this website; When you use our website, you can identify and confirm your identity; Let you get the service for you when you use this website; The relevant business personnel of this website can contact you when necessary; Make it more convenient for you to use this website; The personal data and anonymous data provided by you to us will only be retained until the collection purpose has been achieved, unless they are retained due to applicable laws and regulations. The ownership of personal data and disclosure of all data collected on our website are owned by us and will not be leased or sold to any unrelated third party

4. How do we protect information

For the protection of personal data, we implement appropriate physical, electronic and management measures to protect and guarantee the safety of your personal data. We try our best to ensure that any personal data collected through this website is free from any nuisance of a third party unrelated to us. The security measures we take are not limited to: physical measures: the records with your personal data will be stored in a locked place Electronic measures: the computer data with your personal data will be stored in the computer system and storage media subject to strict login restrictions Management measures: only employees authorized by us can access your personal data, These employees need to comply with our internal rules on the confidentiality of personal data. If you are aware of any security loopholes on this website, please contact us in time so that we can take appropriate actions as soon as possible; Despite the implementation of the above security measures, we cannot guarantee the absolute security of data transmission on the Internet, so we cannot absolutely guarantee that the personal data and anonymous data you provide to us through this website are safe at all times. We will not be responsible for any unauthorized access to your personal data, and we will not be responsible for any losses and damages incurred or caused in this regard.

5. Juvenile Protection Law

The minor has provided personal data to this website without the approval or consent of any parent or guardian. Please contact the public telephone number and customer service telephone number on this website in time to ensure that the data are removed

6. Revision and effectiveness of privacy policy

With the expansion of the service scope of this website, we may revise the Legal Statement and Privacy Policy from time to time, which forms a part of this Legal Statement and Privacy Policy. In order to prevent you from being informed of such revisions, please read this Legal Statement and Privacy Policy frequently. In any way, if you continue to use our services, you agree to be bound by the revised Legal Statement and Privacy Policy